Influence of Spinning Parameters and Recovered Fibers from Cotton Waste on the Uniformity and Hairiness of Rotor Spun Yarn

Halimi Mohamed Taher, Ph.D., Azzouz Bechir, Ph.D., Ben Hassen Mohamed, Sakli Faouzi

Textile Research Unit of ISET, TUNISIA

Correspondence to:

Halimi Mohamed Taher, Ph.D. email: taheeer@yahoo.fr

ABSTRACT

Improving raw material exploitation has become the most important challenge facing scientific and industrial community. In this paper, we have studied the effect of percentage of fibres recovered from cotton wastes and different spinning parameters on the hairiness, the uniformity and the level of irregularity of the rotor yarn. Results indicate that yarn count, rotor parameters (diameter and form) and rotor speed have an effect as significant as waste proportion. With a good choice of spinning parameters, an introduction of 25% on waste in the first passage in the drawing frame does not alter the uniformity and the appearance of rotor yarn.

KEY WORDS

Fibers recovered from cotton wastes, spinning parameters, yarn quality, experimental designs.

INTRODUCTION

In spite of the technical evolution for different blowroom machines, generated wastes in cotton spinning mill contain a great rate of fibers (F. Leifeld (1996), I.Hanafy (1997)). Raw material prices, energy and labour costs have risen since many years. In order to improve raw material exploitation, spinners have to provide a high-cleaning efficiency during the blowroom and recover fibers from wastes. The reuse of

recovered fibers in spinning, has been discussed in many papers. Hanafy (1996) concluded that it is possible to produce a yarn with 100% of recovered fibres from cotton waste using the Siro spun principles. Bruggman (1998) confirmed that recovered fibers can be used for the open-end spinning. Wulfhorst (1984) concluded that these secondary raw materials can be blended with raw materials with a percentage up to 20%, without noticeable changes in yarn quality (Wulfhorst (1984). In a first study, we (Halimi et al 2007) have discussed the effect of recovered fibers on the rotor yarn quality. A quality index, taking into account the tenacity, the elongation and the yarn regularity, is defined and discussed in order to optimise the waste portion and the spinning parameters. In addition, many other yarn characteristics are very important to identify the yarn appearance. That is why, in the following study, we try to evaluate the effect of both the ratio of recovered fibers and some spinning parameters on some yarn characteristics such as hairiness, irregularity, thin places, thick ones and neps.

MATERIALS AND METHODS

In this study cotton wastes, of different origins, were collected from opening and cleaning machines and cards. These wastes were passed into a filter in order to reduce impurity in cotton and were strongly compressed into bales. Greek cotton has some properties, especially length that allows it to blend with recovered fibers. For this reason, the Greek cotton was chosen for all mixtures in different proportions. Table I presents a statistical summary of raw fiber property .

The processing steps and used machinery for impurity reduction are shown in Figure 1. The mix was processed after carding at the first passage in the drawing frame. Another passage is used in order to improve the homogeneity of the mixing. The linear density of the second drawing sliver was 4,45 (Ktex).

Slivers were used to produce yarns on Schlafhorst Autocorro rotor spinning machine. In order to reduce the effect of one spindle on the yarn characteristics, ten spindles were used for each mixture. These were selected at random within the machine. The mechanical properties of yarn were tested by the USTER TENSORAPID whereas unevenness, hairiness and irregularity were measured using the USTER TESTER 3.

The method of experimental designs has been used in this study. This method consists in an optimal number of tests keeping a high quality of results. The main effect plots and the analysis of variance were used for statistical analysis of the results. This analysis consists of calculating statistic parameters that indicate whether the factors are significantly related to the response data and each factor’s relative importance: the mean sum of squares (MS), the F-statistic (F) and the p-value (P) in the analysis of variance table indicate the relative importance of each factor to the response.

The p-value represents the probability of rejecting the null hypothesis when it is actually true. The smaller the p-value, the smaller the probability is that you would be making a mistake by rejecting the null hypothesis. A commonly used cut-off value for the p-value is 0. 1, for example, if the calculated p-value is less than 0.1 the null hypothesis is rejected. So the factor will have a significant effect on the response.

The overall properties of yarn produced from recovered fibers from cotton wastes are mainly related to raw materials properties and spinning process. The metric yarn count (Yc), twist factor (Tf), opening roller speed (Os), rotor speed (RS) and rotor type (Rt) take four levels. This choice can be explained by the required quality of yarn made from recovered fibers from cotton waste.

On the other hand, in order to determine with high precision the optimum percentage of recovered fibers from cotton waste ratio that we can introduce in the blend, the proportion of waste (Wp) in yarn takes eight levels varying from 0 to 100%.

Table II presents the combination of the spinning parameters and proportion of waste that were arranged according to a fractional set (32 experiments). The factors and levels used are shown in Table III.

RESULTS AND DISCUSSION

In general, the spinner may define yarn quality as an index of appearance, strength, uniformity and level of irregularity. The basic aim of our research was to determine the influence of the spinning parameters and waste ratio on the hairiness, the uniformity and the level of irregularity of rotor yarn. The results of the experiments are shown in Table IV.

Hairiness

Yarn hairiness H, is one of the most important parameters influencing the yarn’s use in terms of final product appearance (Lidia, Danuta (2007)).According to table V results the parameters Rt, Or, Tf and Yc have a significant effect (p<_ 0.1) on the hairiness of the

yarn. Whereas Rs and wp have not the same effect

(p >_ 0.1).

According to p-value, the significant parameters can be classified according to the level of importance as

Rt >_Yc>_Tf>_Or>_ Rs >_ Wp.

Figure 2 shows that the rotor type has an important effect on yarn hairiness. Using a T40 rotor rather than U46 reduce the yarn hairiness by 31%. Low hairiness values are obtained with low opening roller speed (7000r/min) and high opening roller speed (8800r/min),

But the hairiness increases at the speed (7500 r/min) and (8200r/min).

The rotor speed (Rs) seems to have a slight effect on the yarn hairiness. It confirms the results given above (p>_ 0.1). The yarn count has an important effect on the yarn hairiness. In agreement with scientific and technical literature, thick yarns have upper hairiness values than thin ones (Klein, (1993)). When Wp passes from 0% to 100%, the yarn hairiness varies between 7.8 and 9.3 only by 17.7%. This result shows that these parameters do not have an important effect on the yarn hairiness.

Irregularity CV%

According to the results from table VI, the parameters

Rt, Rs, Yc and Wp have a significant effect (p<_ 0.1) on

the yarn irregularity. Whereas Or and Tf have less

effect on the yarn irregularity (p >_ 0.1).

According to p-value the parameters can be classified according to the level of importance as:

Yc >_ Wp >_ RS >_ Rt >_ OR >_ Tf.

Figure 3 shows the effect of the different factors on yarn uniformity. Results indicate that the coefficient of variation (CV%) increased as yarn count increased.

Another influential parameter is the waste proportion Wp. When the Wp passes from 0% to 100% the CV% increases by 10%. In addition, we note a minor variation for Wp up to 25%.

The Rotor speed seems to have an important effect on the yarn uniformity. In most cases, an increase in rotor speed led to gradual deterioration in yarn uniformity. These results are in agreement with Schubert and salzer and LX KONG results (Klein, (1993)).

The effect of rotor type is represented in the Figure 3. The good choice of the rotor parameters (diameter, form and speed) has an important effect on the yarn uniformity. Using a T40 and T46 rotor rather than U40 and U46 improves the yarn uniformity. Moreover, results indicate that rotor geometry is more influential than its diameter.

Thin places

Yarn faults in the shape of thin, thick places and neps are decisive on the external appearance of yarns and the obtained products. An optimum solution is the possible smallest number of faults[8]. According to table VII results, the parameters Rt, and Yc have a significant effect (p<_ 0.1) on the yarn thin places. Whereas OR, RS,

Tf and Wp do not have the same effect (p >_ 0.1). According to p-value the parameters can be classified according to the level of importance as:

Yc >_Rt>_Rs>_Wp>_Tf>_Or

Figure 4 shows the influence of the different factors on the thin places in yarn. Rotor type and yarn count seem to be the most influential parameters. As we noted for the coefficient of variation Cv%, using a T40 and T46 rotor rather than U40 and U46 decreases the number of irregularity in the yarns. Similarly, thin places decreased for thick yarn. Indeed, the number of fibers in yarn section is proportional to the yarn count, the latter decrease improves the yarn homogeneity. Consequently, the number of thin places decreases.

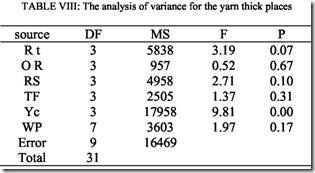

Thick places

From Table VIII, we can conclude that only the parameters Yc ,Rt and Rs have a significant effect (p<_ 0.1) on the yarn thick places. Whereas Or, Wp and

Tf have less effect on the yarn irregularity (p>_ 0.1).

According to p-value, the influent parameters can be classified according to the level of importance as:

Yc >_Rt>_RS>_Wp>_Tf>_Or

Figure 5 shows the effect of the different factors on the thick places in yarn. Results indicate that thick places increased as yarn count increased too. This means that the homogeneity of the yarn is improved by 74% when the Yc passes from 20 to 10 .Similar results are also obtained for rotor type. T40 and T46 rotor improve yarn homogeneity and reduce thick places in yarn.

Rotor speed seems to have a considerable effect on the thick places yarn. Working with high speed affects negatively the yarn homogeneity.

Neps

According to p values given in Table IX , only the

yarn count Yc has a significant effect (p<_ 0.1) on the

neps . Whereas Or, Wp, Tf ,Rt and Rs have not

(p >_ 0.1).

According to p-value, the parameters can be classified according to the level of importance as:

Yc >_Rt>_RS>_Wp>_Tf>_OR

Figure 6 shows the effect of the different factors on the neps in yarn. In most cases, an increase in yarn count and rotor speed led to a gradual rise in the number of irregularity in the yarn. On the other hand, The neps are down by 43% when the opening roller speed passes from 7000r/min to 8800 r/min. This result further demonstrated that the separating action of the opening roller affects yarn irregularities. This variation leads to deteriorating yarn quality by poor separating action.

In addition to results from an earlier publication (Halimi et al 2007), it seems that recovered fibers from

cotton waste can be mixed in a proportion between 15% and 25%.without noticeable changes in yarn end use quality. Taking into account that the yarn quality is considered for the majority of spinner as an index of appearance, strength, uniformity and level of irregularity.

CONCLUSION

Our objective in this work was to establish the effect of recovered fibers from cotton wastes and different spinning parameters on the rotor yarn uniformity and appearance. In general it can be said that the spinning parameters are as significant as the rate of waste.

To sum up, Waste portion, yarn count and rotor type have the most important effect on the blended yarn. The introduction of 25% of waste in the first passage in the drawing frame does not alter the appearance, level of irregularity and the yarn uniformity. The yarn hairiness decreases with the yarn count. On the other hand, as the latter increases, the number of faults rises too. Using a T40 and T46 rotor rather than U40 and U46 decreases on the coefficient of variation and the number of irregularity. Results from this study can provide some insight into the reuse of recovered fibers from cotton waste in a spinning mill but it remains a need for more primary raw material variation to identify the potential of changes in yarn’s properties. The mixture of recovered fiber with synthetic material and its effect on yarn quality can be the subject of subsequent research.