Object : To open and clean the cotton.

Type : Loose feeding pin opener, Major cleaning point.

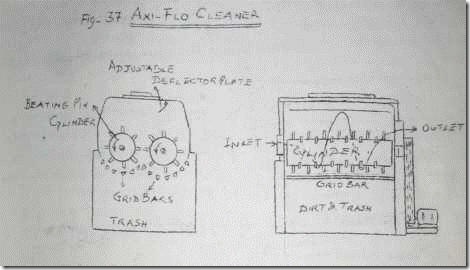

The coton is drawn into the Axi-Flo machine through inlet Pipe. The construction of the two beating cylinder with grid bar arrangement, is clearly shown in figure.

Opening and cleaning of cotton is achieved by the repeated beating action of the rapidly revolving two beating cylinder on cotton against grid bar. Trash particles from the cotton is extracted through the grid bar and is collected below the grid bar.

Smaller tufts that are already sufficiently opened for a quick and thorough cleaning, thus leave the Axi-flo earlier without receiving unnecessary beating. This prevents loss of good fibre, formation of neps and fibre entanglement. Fibre contained in large tufts cannot get entangled or lost through the grid. They remain in the machine till they are transformed in to small tufts and release their impurities easily.

An adjustable guide plate fixed to the inlet pipe control the angle at which the tufts approach the right beating cylinder.

This cylinder takes the tuft downwards, guides them over the broad waste grid and throws them up against the adjustable defector plate. The defector plate directs the tuft stream within the reach of the left cylinder which then passes the material over its own grid and transfers the 1arger tufts back to the right cylinder. The position of the adjustable guide plate between the two cylinders decides how long the tufts remain under the influence of each cylinder.

The angular position of the bar is adjustable for each set separately. Each set of grid bar can be raised or lowered to alter the distance between the grid to the end of the spike. It is thus possible to adjust the amount of waste and its quality to the requirements and the different types of raw material.

![clip_image012[1] clip_image012[1]](https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEg8zn4VOvJNiFFfXyr0K3xuiG7lwhwOWe52qpdkIdLd6Y1bqel-7ARRcJSKvwAjmqF-NryHsCrXLk9Jr1RsV0Aj_Z57y0NFNRq9-wkQBlztpT391GEpvsclnV6YbEvtS6TRQftJ8adtHJI0/?imgmax=800)