Achievements

Perfect and Homogeneous blend is achieved, ii) simultaneous mixing by doublings' over an extended period of time is achieved.

The cotton bales are opened and premixed by bale opener.

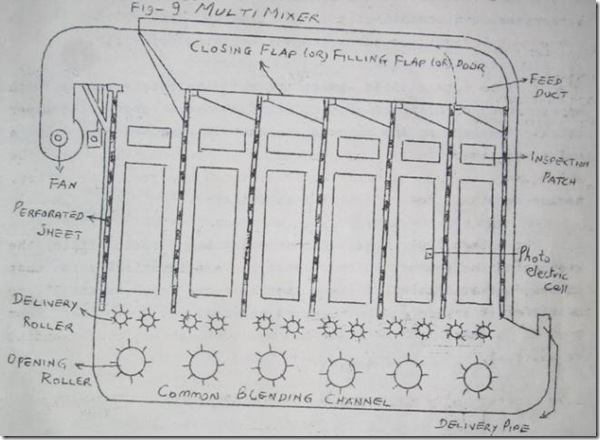

This blend is blown by the material transport fan and conveyed into the feed duct above the hopper.

The charging of the multimixer starts with the first hopper at the end of the feed duct.

It is filled only to just below the photo cell situated in the adjacent hopper, then the closing flap of the second hopper * is opened by push button operation..

Second hopper is charged” to a rather higher than the first. The charging level of the hopper rises uniformly up to the last hopper which is fully charged, when the last hopper is full the Closing flap shuts automatically and charging restarts with first hopper, as soon as the level second hopper has dropped below the Photo Electric cell.

whilst the last hopper is being charged, material transport is switched on and material in the hoppers starts to drop.

When the charging level rises, more and more of the holes in the perforated plate of the upper part of .hopper are blocked with material. This increases the pressure the conveyor air. Once a pre-selected pressure is reached, which corresponds to a particular charging level, an electronic switch closes the flap of this hopper and opens up the flap of the next hopper."

The base of each hopper is closed by a pair of deliver roller which transfers the material gradually and uniformly to an opening roller. The delivery rollers of the entire hopper are

two variable speed motor with control range up to 1 : 6 in this way it is possible to adjust the output of multimixer to the feed requirement of the subsequent machine.

Opening roller gently loosen the material into tufts and

deliver them into the blending channel from which they are sucked

by the subsequent condenser.