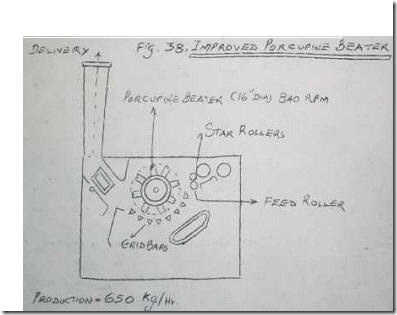

(Improved porcupine opener)

Object: To open and clean the cotton.

A controlled motor with an infinitely variable speed unit drives a star roller and a pair of feed roller. Star roller drive the material from the delivery funnel of the preceding machine to the feed roller. Pair of feed rollers are fluted and spring loaded.

Due to heavier beating of the beater blades of the beater on compressed sheet of cotton delivered from feed roller against grid bar, the cotton tuft is opened and impurities are extracted and passed through the spacing of the grid bar.

The beater blades have double notched and bolted to the cylinder in pairs. This types of fixing is rigid and no vibration during beating action, so, beating is accurate and definition. In conventional porcupine opener, individual striker blades are revetted and they are not very rigid due to the free length of blades and method of fixing to the discs.

The waste grid consists 25 specially profiled steel bars and can be adjusted during operation. A graduated scale helps the repositioning for favourable settings.