One of the great things about tablet weaving is that you don’t need a loom to do it. You can tie one end of your warp to a table leg, a door knob, or your big toe, tie the other end to your belt or hold it in your hand, and weave away! You can even weave with a friend each holding one end of the warp.

Some people, however, find it easier or just more convenient to stretch their warp on something stationary. In the Middle Ages, a pair of uprights connected by one or two horizontal braces was the usual way to do this. The uprights might be anywhere from waist- to head-high on a standing adult. The weaver sat on a chair, stool, or bench, with the warp running across her or his lap at a convenient height. The sketch at right is based on an image from a medieval manuscript, and will give you a good idea of how this worked.

If you would like to do something similar, you still don’t have to make or buy any special

equipment. You can run your warp between the legs of an upside-down coffee table, the handles of a basket, the ends of a fruit crate, or the sides of a picture frame with the back taken off. But if you want a special tablet-weaving loom, you might consider one of the following options.

MaStER HERVEUS’ QUICK-and-SlEaZY StUdEnt LOOm:

This design was created by Herveus d'Ormonde (whitewolfandphoenix.com). These directions were written by Coblaith Muimnech (Coblaith@ sbcglobal.net). You may distribute them as you wish, provided you credit the sources of both the words and the idea and do not charge anyone for them.

Cut two eight-inch-long pieces of doweling and a three-or four-foot length of two-by-four lumber.

About an inch and a half from each end of the two-by-four, on the narrow edge, drill a two-inch-deep hole that slants slightly outward. It should be just barely bigger in circumference than your dowel.

Insert the dowels into the holes and test the fit. They should be just loose enough to turn in the holes. Sand or shave them a little if you need to.

You can use a circular warp or tie the ends of your warp to the dowels. To use the loom, either set it on a table with the dowels upright, as shown to the left, or set one end on your lap and one on a table or the ground.

If you’d like to add a little more flexibility to the loom, you can drill an additional hole between the first two, near and slanted away from one of them, and insert a shorter length of dowel to make a cleat.

For tension adjustment or for warps longer or shorter than the peg spacing, you tie a cord to one end of the warp and tie it off to the dowel, or lead it around the dowel and use the cleat or the other dowel to secure it.

TOLI’S L-SHAPED MINI-LOOM

This design was created by Toli the Curious (tmyers2@unl.edu; http://anvil.unl.edu/toli/loom.html). It is suitable for tablet-weaving and simple rigid-heddle weaving. He uses scraps from “cheap particleboard shelves” to make his, but believes quarter-inch masonite would be strong enough. Others have found MDF holds up well, and catches the thread less than does particle board. You could also make these from hardwood boards, though that would significantly increase your costs. Soft wood, like pine, is a poor choice for this project; it doesn’t handle well the stresses weaving puts on the loom.

These directions were written by Coblaith Muimnech (Coblaith@ sbcglobal.net). You may distribute them as you wish, provided you credit the sources of both the words and the idea and do not charge anyone for them.

Materials List

one 12-inch wide board, 18 inches long

one dowel, 1 inch or more in diameter, at least three times as long as you want your finished loom to be in width

two hanger bolts (bolts threaded like a wood screw on one end and like a lag bolt on the other); Toli uses 2 1/2” long quarter-inch hanger bolts with 20 threads to the inch on the lag end.

two 3-pronged T-nuts (nuts designed to fit into a hole in wood, with prongs to hold them in), matching the hanger bolts’ lag ends in diameter and thread count

four lag bolts, the same diameter as the hanger bolts

one piece of 1-by-2 lumber, long enough to yield two tensioning knobs (1 3/4” to 3” long, each, depending on how big you want your knobs to be)

Tools Needed

a coping, scroll, or jig saw a miter box and miter saw locking pliers

a drill and two bits, one slightly smaller in diameter than your bolts, the other the same size as the barrel of your T-nuts

Preparing the Components

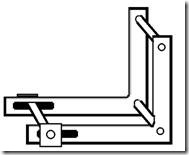

Cut two identical L-shaped pieces from the board, as shown in the first illustration at right.

Using the smaller bit, drill a hole near the end of the shorter leg of one “L” and one in the corner. Then use the larger bit to drill two holes six inches or more apart near the end of the longer leg.

(The placement of all four holes is shown in the second illustration.)

Align the two pieces and clamp them together. Drill through the holes in the first one into the second, creating matching holes.

Use your coping, scroll, or jig saw to connect the two holes on the longer leg of each piece, making a slot like that shown in the third illustration above.

Cut three lengths of dowel, each as long as you want the loom to be wide. Use a miter box and saw to ensure square cuts.

Using the smaller bit, pre-drill both ends of each length of dowel. Take care to center the holes and drill parallel to the sides of the dowel. (This will be easier if you use a drill press.)

Clamp your locking pliers onto the lag end of one of your hanging bolts, and use them to screw the wood end into a pre-drilled hole in a dowel. Repeat with the other hanging bolt and the other end of the same dowel.

Cut two knob-sized pieces of 1-by-2 lumber. Using the larger bit, drill a hole through the center of each one. Insert a T-nut into each hole and tap it down.

Sand all your pieces smooth. Decorate the sides and knobs, if you wish.

Assembly

Attach the two plain dowels to the side pieces, using lag bolts through the pre-drilled holes.

Slide the remaining dowel between the sides, slipping the protruding ends of the hanging bolts into the slots. Screw the knobs on. Tighten them down to keep the dowel stationary (an inch or two from the slot-end farthest from the corner) until you’re ready to adjust your tension. Then loosen them, move the dowel to its new position, and tighten them again.