BT 903 and BT 905 two concepts

BT 923 rotor spinning machine

BT 923 - Rotor Spinning Machine

New Concept for Productivity, Ergonomy and Selfguarding

BT 923 - Production

Increased Rotor Speed 110 000 rpm thanks to:

New spinbox concept with

optimised fibre transport

channels

Rotors without holes combined

with central suction system for

technology air

New design of a bearing with

ceramic balls

Increased Delivery Speed 200 m/min thanks to:

new concept of bearing the delivery

shaft

hydraulic shock absorber for bobbin

arms preventing vibration and

winding malformation

pneumatic loop compensation

Production Increase

Example for Ne 10 production:

· BT 923

(320 SBs, 100 000 rpm, 180 m/min)

- 194 kg per hour

· other semiautomated machines

(320 SBs, 90 000 rpm, 160 m/min)

- 174 kg per hour

BT 923 Enhanced Ergonomy

· Lower machine height for easy operation

· Section lay-out to accommodate 18“ cans

· Independent drives

· Two transport belts

· Automatic lifting of bobbin arms

· Dissassembly of spin box

with minimum instruments

· New display

Cost Savings with Large Cans (18 1/2” versus 16”)

BT 923 - Independent Side Drives

Benefits of independent side drives

· Packages with different counts or length or

winding density or material or color can be

produced on each side

· Increased effciency producing small lots

· Reduced running costs by independent

maintenance

BT 923 - Two Transport Belts

· No mixing of bobbins if two

different yarns are produced

on each machine side

· Temporary stock of full

bobbins

· Savings on labour costs

New Spin Box C 120 Components

· New bearing with ceramic balls

· Smaller diameter of the opening

roller (65mm)

· Insert with exchangable caps

· New concept of the feeding clutch

- precising of feeding = advantage

for slub function

· Spin box disassembly without

tools and jigs(except rotor)

New Technology Parts for C 120 Spin Box

Exchangable insert caps

Costs savings for

the change of spinning

specification!

New graphical display

· More data illustration

· Better arrangement of data

· Easier orientation among

functions

BT 923 - Yarn monitoring and selfguarding

New Yarn Quality Sensor - IQplus®

· Optical cleaner with new chip

technology

· Higher resolution

· Higher data reading (20 points per 1 ms, e.g. 10 points per 1 mm of yarn for the delivery 120 m/m i n)

· Better resistance against surrounding light and dust

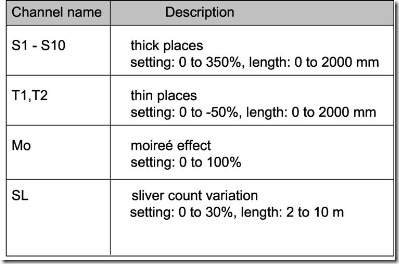

New Channels

Classification of Faults

BT 923 - new benchmark for semiautomated machine

· Ne 3-40 yarn count range

· 110 000 rpm

· 200 m/min delivery speed

· 320 spinning positions

· AMIspin® for electronically controlled piecing

· IQplus® yarn clearer for yarn quality

· Independent side drives for flexibility

· Rieter slub yarn device for structured yarn